The neutron diffraction method4 measures strain directly through changes in the lattice spacing as in X-ray diffraction, and is essentially unaffected by other sample properties such as texture. Because of the neutrons' ability to penetrate inside bulk materials we believe it is likely to become an important technique for internal stress measurement. However its drawback is that high resolution is needed, and neutron beams of sufficient intensity are only available at reactors or accelerator-based neutron sources. Samples may be transported to the neutron beam, but conventional methods must still be used on the factory floor.

In the following sections we outline the principles of the neutron diffraction technique for measuring internal stress. We then describe two different diffractometers with sufficient resolution to measure the internal strains in steels. We then describe measurements on a 6 mm (1 in) mild steel bar subjected to defined external stresses below its elastic limit. Lastly we describe measurements of the internal stress in a 25 mm (1 in) thick bar deformed beyond its elastic limit.

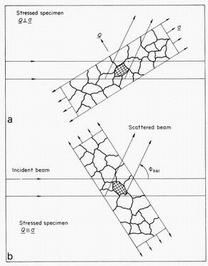

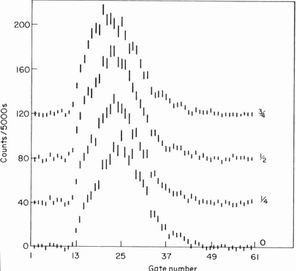

Fig. 1 Neutron powder diffraction.

Neutrons of a particular wavelength are selected from the reactor beam by reflection from a crystal

monochromator. A polycrystalline sample contains grains of all

orientations which scatter at different angles

fhkl according to their

plane spacing dhkl. The scattering cones are intercepted by scanning

the counter angle f.

The neutron diffraction technique

Neutron beams from reactors have a wavelength of the

order of 0.1 nm (1 Ǻ) - similar to that of an X-ray beam. ,:

They differ from X-rays in interacting only weakly with

matter and so penetrate several centimetres in most materials.

A neutron beam monochromated to a particular wavelength

l

is diffracted by a polycrystalline material into a

series of cones as shown in Figure 1. The scattering angles

fhkl

of these Debye Scherrer cones measure the lattice

spacings d^ of the various atomic planes with Miller

indices hkl.

The scattering angles are related to the d

spacings through Bragg's law;

l = 2dhkl

sin(fhkl/2).....(1)

An internal stress causes a strain which changes the lattice

spacings d by a tiny fraction

ld/d, of magnitude a few

times 10-4, which must be deduced from the consequential

changes Df in scattering angles.

Most conventional neutron

diffractometers have insufficient angular resolution to resolve

such small changes. The possible ways of improving the

sensitivity are made clear by differentiating Equation 1.

Dd/d =

Dl/

l +

cotf/2 +

(Df/2) .....(2)

As the angle f increases

towards back scattering (f = 180o)

the term cotq reduces to zero,

and can therefore be made

small with consequent improvement in resolution.

Alternatively the angular resolution Df

can be improved, for

example by defining the beam by multi-slit Soller collimators,

but this results in a proportionate loss in intensity.

In order to reduce the contribution of the Dl/

l term in

Equation 2, we consider the usual method of monochromating

neutrons by Bragg reflection from a large single

crystal as in Figure 1. The wavelength is determined by the

monochromated beam angle fM

and the spacing dM of the

crystal planes held at the appropriate orientation. The

wavelength resolution term is then

Dl/

l =

cotfM/2 +

(DfM/2) .....(3)

High resolution is obtained either by going to high angles

fM

or by improved collimation. Of the two diffractometers

we describe, one uses scattering angles within the

range 5o to 10o from back scattering in both

fM and

fhkl(j) to

obtain the necessary resolution without exceptional collimation.

The other uses high angles of order 110o coupled

with high (10') collimation.

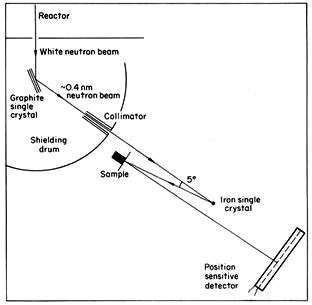

Fig. 2 A diffraction experiment selects crystallites with lattice

planes perpendicular to the direction Q at the orientation appropriate

for Bragg reflection at the scattering angle

f. (a) If the sample is

placed with the stress perpendicular to Q, contracted plane spacings are observed.

(b) If the stress is parallel to Q, the plane spacings are expanded

The detection of the lattice strain tensor by

diffraction

Figure 2 shows schematically a large, stressed, polycrystalline

sample placed in the sample position of a

neutron diffractometer. Of all the grains in the sample

only those whose lattice planes are oriented to allow Bragg

reflection will contribute to the scattered beam. Bragg

reflection occurs when the normal to the reflecting planes

bisects the incident and scattered neutron beams and is

therefore parallel to the change in neutron wave vector,

conventionally denoted as the scattering vector Q.

If the direction of the stress

s

in the sample lies along Q, (Q ||s )

the appropriate lattice spacings will be slightly increased. If it

lies perpendicular to it the same lattice spacings

will be slightly contracted because of the Poisson's ratio

effect in the bulk material acting on each crystallite.

By rotating the specimen in the diffractometer and

measuring the d spacing shift as a function of orientation,

the principal axes of the strain tensor can be determined.

(Shear strains giving the off-diagonal terms in the strain

tensor have different effects.) The stress can then be

calculated from the strain knowing the elastic moduli from

bulk measurements.

Figure 2 also illustrates how a relatively thin incident and

scattered neutron beam can be used to define a precise

volume within a large bulk specimen and so measure stress

as a function of position over the specimen volume. The

volume is best defined when

fhkl is around

90o, and least well defined in the back scattering geometry.

Fig. 3 The Double Back Scattering Diffractometer

The Harwell double back scattering diffractometer

Figure 3 shows the layout of the double back scattering

(DBS) diffractometer at Harwell with which residual stress

effects were first observed. The diffractometer was modified

from the MARX spectrometer on the PLUTO reactor. A

preliminary crystal monochromator of pyrolitic graphite

selects a roughly monochromatic beam of about 0.4 nm

wavelength. Selection of a very narrow wavelength band is

then achieved by Bragg reflection from a single crystal of

pure iron aligned so as to reflect from its 110 planes at a

scattering angle

fM= 174.15o corresponding to 5.84o from

back scattering. An iron crystal was chosen since the use of

back scattering from both monochromator crystal and

sample implies a match between the d-spacings dM and

dhkl which is in practice only achieved by choosing the

same plane of the same material. Iron or ferritic steel

samples can then be placed in the beam reflected from

the iron single crystal and the 110 powder reflection

observed. Scattered neutrons are detected by a position-

sensitive detector covering an angular range of about 3o to

28o. No special collimation is used, but the size of an

8-mm-wide beam between the iron single crystal and the

sample gives a geometric collimation

a1~= 0.9o. The

counter resolution of 6 mm together with an 8 mm wide

sample gives a scattered beam geometric collimation

a2 ~ 0.5o.

The resolution calculated using Equations 2 and

3 (and so neglecting any focussing4 considerations) is then

Dd/d ~ 0.5 x 10-3.

Collimation in the vertical plane is

determined by the heights of the iron single crystal,

sample and counter, all of which are about 40 mm. This

degree of vertical collimation gives a negligible contribution

to the resolution.

In fact all the samples of iron or steel investigated gave

widths appreciably larger than this calculated resolution.

Even a sample of iron powder, strain-annealed by heating

to 550oC for one hour, gave a width

Dd/d ~ 1.5 x 10.

Our annealed steel bar 5 mm thick gave a width

Dd/d ~1.8 x 10-3.

Such widths can be due to microscopic

internal stresses within a single grain of the material, such

as those caused by dislocations or defects within the grain,

or from microscopic stresses varying randomly from grain

to grain produced by, say, an impurity phase. This micro-

scopic stress can be measured by diffraction only after

deconvolution of a term

Dd/d ~

l/2L

depending on the

size L of the diffracting crystallites. The macroscopic strain

spans several grains of a material and so gives a uniform

shift to the peak angle rather than a width. The minimum

detectable shift, which determines the minimum detectable

stress, is typically at least 1/10 of the width of the observed

peak. The actual value depends on the statistics of the

measurement and the degree to which the line-shape is

well-defined.

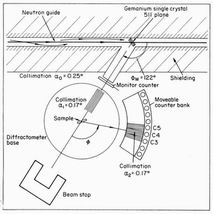

Fig. 4 The modified D1A spectrometer

at the ILL reactor. The high

resolution

Dd/d ~ 1.4 x 10-3 at 109°

is achieved by relatively high

monochromator and scattering angles, by multislit Soller collimators

before and after the sample, and by employing a 'focussing' configuration

with

f~

fhkl.

Counter 4 was used for all peaks, counters 3 and

5 were used to estimate the background

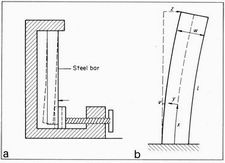

Fig. 5 (a) The modified vice used to apply a quantitative stress to

a mild steel bar. The bar was clamped at its upper end, and displaced

at the vice jaw by turning the screw thread, (b) shows the variables

used in defining the stress

f(x, y) as a function of position on the bar

The modified high-resolution powder diffractometer

The powder diffractometer D1A is situated on a thermal

guide tube from the high-flux reactor at the Institut Laue-

Langevin at Grenoble. It was already noted for its high

resolution5. Its layout is shown in Figure 4. The guide tube

gives an effective collimation

a0= 0.25o for 0.19 nm

neutrons. This is convoluted with the mosaic spread of the

germanium monochromator to give a beam on the sample

with angular divergence 0.67o. Scattered neutrons are

selected by ten Soller collimators of divergence

a2= 0.17o,

each in front of a counter separated by 6o. This configuration

gave a resolution at

f = 109o of

Dd/d = 1.6 x 10-3 as

measured from a strain-free alumina specimen. The resolution

was further improved by the addition of a further

Soller collimator giving a divergence between the mono-

chromator and sample

f=0.17o. This increased the

measured resolution at f= 109o to

Dd/d = 1.39 x 10-3M/d,

marginally less than the resolution calculated using Equations 2 and 3

because, near this scattering angle, focussing

effects are appreciable. With this diffractometer, scans must

be made by changing the scattering angle

f in small steps.

We concentrated most measurements on the iron 311 powder

peak as this came near f = 109o,

allowing focussing effects

to be exploited in improving the resolution. Only one

counter could be used effectively for the scan. The counters

6o on either side were used to estimate a background, although

this was typically only a percent or two of the peak.

Stress measurements in mild steel bar bent elastically

As a test of the method, an extensive series of measure-

ments was performed on a bar of low-carbon mild steel

which could be deformed to a known degree below its limit

of elasticity. The bar had a thickness t=6 mm (1/4 in) and

width w = 51 mm (2 in) and had been heat treated for one

hour at 550oC to remove residual stresses. (The first measurements

were performed on a similar bar of just half the

thickness and width.)

The strain was applied as shown in Figure 5. One end was

firmly clamped, while the other end could be displaced by

distances z by rotation of a vice screw.

The length of the bar between the clamp end and the top

of the vice was l = 214 mm. It had been hoped to measure

the stress directly from the displacement z. The stress

s(x, y) at a position x

from the clamp and y from the

neutral axis would then be given in terms of Young's modulus

E by

s(x, y) = 3E z(l-x)y/l3 ....(4)

This formula failed if z was measured from the vice displacement

as distortions of the clamp occurred. Instead the

curvature of the bar was measured directly by measurements.

of the profile of the bar under various nominal stresses. The

stress is then given simply from the curvature d2 v/dx2 by

s(x, y) = -yEd2 v/dx2 ....(5)

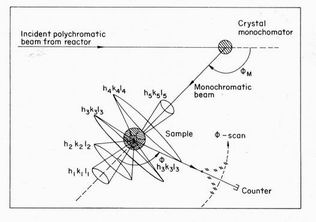

Fig. 6

Scans of the counts recorded by the position-sensitive

detector as a function of the detector gate number. One gate

corresponds to a 1.6 mm displacement and to 0.06o in scattering

angle. The different curves correspond to 0, 1/4, 1/3, and 3/4 turns of the

screw thread of the vice

Profile measurements were performed by mounting the bar

horizontally on a plane table and traversing a height gauge

over the top surface of the bar. Although the height accuracy

was better than 10-2 mm, the need to differentiate

twice led to an appreciable possible error in the calibration

of stress of perhaps 30%. The maximum stress occurs on

the edge of the bar (y = w/2) and near the clamped end

(x = 0). Taking Young's modulus for steel as E = 207 x 109 Pa

(30 x 106 lbf/in2) gave a maximum stress at our largest

nominal displacement of 137 MPa. This is not far below

the yield stress 250 MPa. In fact our smaller bar emerged

from any further displacement with a permanent set at the

clamped end. No observable deviations from elastic behaviour

occurred in our larger bar.

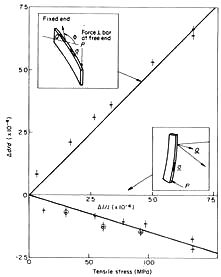

Figure 6 shows experimental results made using the

Harwell DBS diffractometer. The curves are plotted against

channel number of the position-sensitive detector as a

function of the nominal applied stress in turns of the vice

screw. For these data the bar was aligned vertically so that

the normal to the Bragg reflecting planes was perpendicular

to the stress. The actual displacement of the bar was only a

few millimetres and, being along the back scattering direction,

produced no significant effect on the scattering angle.

The displacement due to stress is clearly seen and was

evaluated from the centroid of the peak profile together

with its statistical error. The shifts relative to the unstressed

position were converted into a relative shift

Dd/d

in lattice

spacing using Equation 1. The circled points in Figure 7

are these values plotted against the stress calculated for this

region of the bar using Equation 5. The shift is a negative

one as expected for the Q i a geometry of Figure 2.

Using the D1A diffractometer it was possible to orient the

bar so that reflecting planes with normals Q either parallel

or perpendicular to the stress direction a could be observed.

Examples of the data for Q perpendicular to

s are shown in Figure 8. The

actual linewidth corresponds to

Dd/d ~ 2.3 x 10-3 and is

appreciably larger than the resolution of 1.4 x 10-3. The

lineshape is seen to be close to Gaussian. The peak position

was deduced from a least squares fit of the data to a

Gaussian of variable intensity and width. The total run

time for a scan on both diffractometers was about 10

minutes.

The uncircled points in Figure 7 shows the shifts

Dd/d from

the D1A data plotted against the stress

s(x, y) averaged

over an 8-mm-wide strip near the edge of the bar (x = 30 mm,

y = 48 mm). The upper points correspond to the

Q parallel to the stress

configuration and show positive shifts with a magnitude

about three times as great as the lower points which have negative

shifts measured in the Q perpendicular to

d configuration.

The cental scale to Figure 7 shows the macroscopic strain

Dl/l=0.5wd2v/dx2 ....(6)

calculated from the curvature measured at the experimental points. The upper

line has a slope of unity showing that the macroscopic extension is roughly equal to

the microscopic extension as measured from the lattice spacings.

The lower line has a slope of -0.30. This shows that the microscopic Poisson's ratio

is again roughly equal to the macroscopic Poisson's ratio for steel of 0.30.

Fig. 7 Fractional change in lattice spacings vs stress applied for the

mild steel bar. In the upper graph the Q vector is parallel to the direction

of applied tensile stress a which produces macroscopic strain

Dl/l. Thus the lattice strain

Dd/d is positive and approximates closely

to the macroscopic strain (straight line). In the lower graph the Q

vector is perpendicular to the tensile stress direction and so t^d/d is

negative. The straight line assumes Poisson's ratio is -0.30. The

insets show the scattering geometry

-------------------

Fig. 8 D1A Data Scans with Q vector along the stress direction

for 0, 1/8,1/4,3/8, 1/2 turns of the vice-screw

The slopes of the lines define for us the calibration of the

stress for mild steel in terms of d spacing shifts, and we may

go on to measure stresses in other mild steel samples from

the measured shifts.

Residual stress measurements in a plastically

deformed bar

A second series of measurements was made on a mild steel

bar of 25 mm (1 in) thickness, and 51 mm (2 in) width which

had been subjected to sufficient stress to bend it beyond its

elastic limit into a permanent curve of radius about 500 mm

across the 51 mm width. It therefore contained large residual

strains up to and beyond the elastic limit. It was placed on

the D1A diffractometer with the reflecting planes along the

bar. The magnitude of the stress across the width of the bar

was measured by raising the bar across the incident beam

narrowed by slits to 7 mm height. The results are shown in

Figure 9. They have been converted into stresses from the

calibration curve given by the slope of the upper line in

Figure 7. The bar clearly contains an elastically deformed

central region although the neutral axis does not coincide

exactly with the bar axis. The outer regions contain the

plastically deformed metal.

The orientation of the residual strain was measured experimentally

for a position 13 mm from the strained edge of

the bar by performing scans as a function of the angle o

shown inset in Figure 10. The position of maximum shift

Dd/d defines the

strain direction to lie along the bar to

within an accuracy of a few degrees.

Fig. 9 Variation of residual stress with position across the deformed steel bar

Fig. 10 The Bragg scattering angle from the plastically deformed

bar plotted against the angle of the sample near the position (at 90o)

when plane spacings perpendicular to the bar were being measured.

The minimum near 90o shows that the stress lies along the direction

of the bar

Conclusions

High-resolution neutron diffraction gives a measure of

internal stress within bulk materials of up to several

centimetres thickness which can be calibrated absolutely

and is not affected by texture or sample surface. Measurements

take about 10 minutes on the two diffractometers described.

However, the method is restricted to samples

that can be taken to a neutron source of reasonably high

flux. The sensitivity for samples free of microscopic strain

is as high as a few percent of the elastic limit strain, but this

sensitivity is reduced for samples whose microscopic strain

is large.

Acknowledgements

The authors are grateful to Vie Rainey from Harwell and

Steve Heathman of Grenoble for help with the apparatus

and to Colin Sayers for useful discussions. Crown Copyright

is reserved on this paper, Copyright HMSO 1981.

References

1 James, M.R. and Buck, 0. Critical Rev Solid State Mater Sci

9(1980) pp 61-105

2 Cooper, W.H.B., Saunderson, D.H., Sayers, C.M., Silk, M.G.

'Ultrasonics and the residual stress measurements problem'

AERE report R-9588

3 James, M.R. and Cohen, J.B. Treatise on Mater Sci and Tech

19A(1980)p 1-62

4 Bacon, G.E. Neutron Diffraction (Clarendon Press, Oxford

1975)

5 Handbook of facilities (Institut Laue-Langevin, 156X,

Grenoble, France)

Authors

Drs Allen, Hutchings and Windsor are in the Materials

Physics Division, AERE, Harwell. Dr Andreani is on

attachment to Materials Physics Division from Frascati,

Rome, Italy. Enquiries about this work should be directed

to Dr C.G. Windsor, Materials Physics Division, Building

418.15, AERE, Harwell, Oxon, 0X11 ORA, UK.